Chaquen Rover Overview

The Chaquen Rover is a cutting-edge robotic platform designed by UMNG’s engineering team for exploration in challenging environments, simulating Martian conditions. The project combines advanced mechanical, electronic, and software systems to achieve remarkable performance in robotics.

Use the interactive 3D model to explore the rover’s design and its high-performance components.

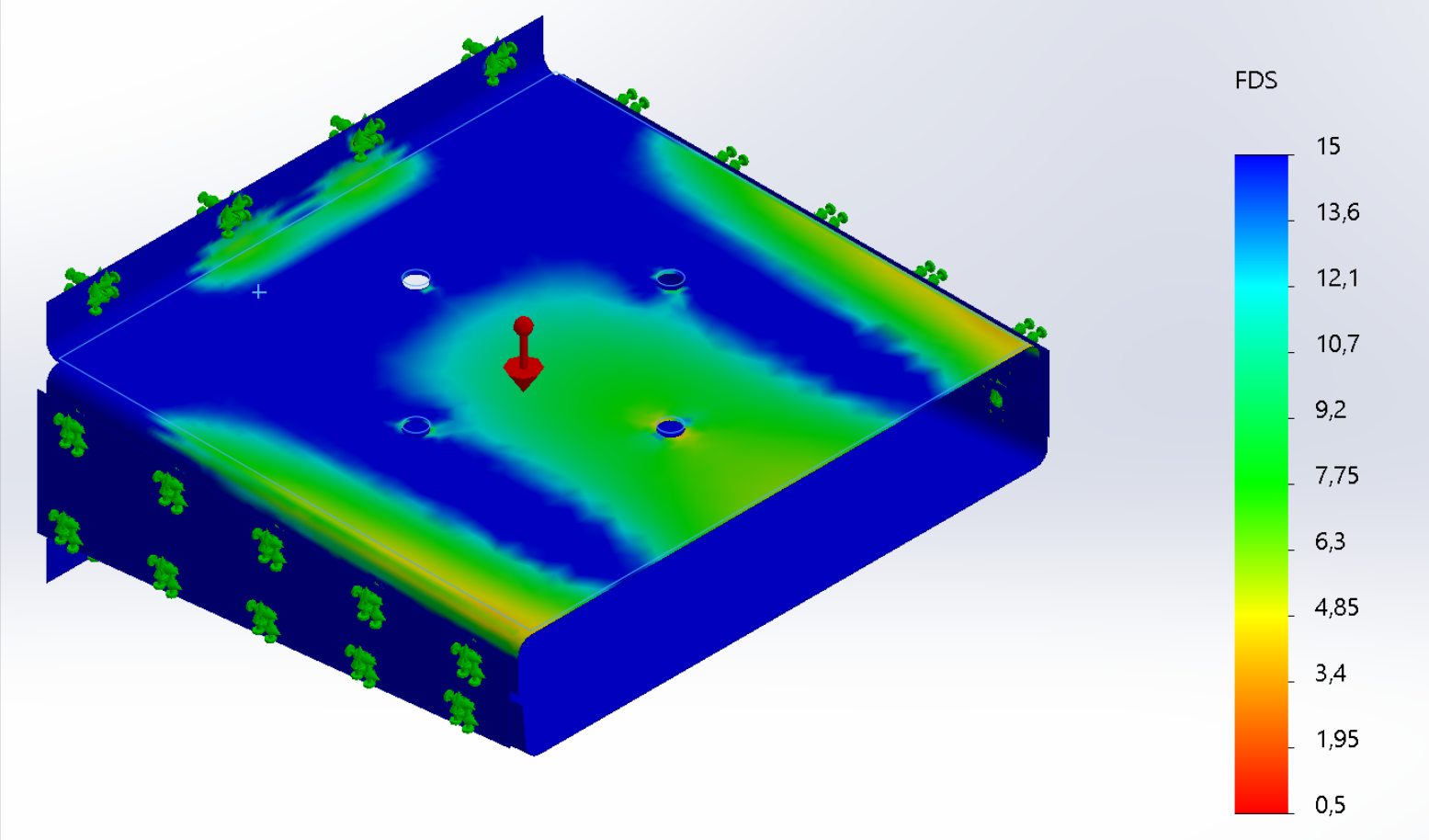

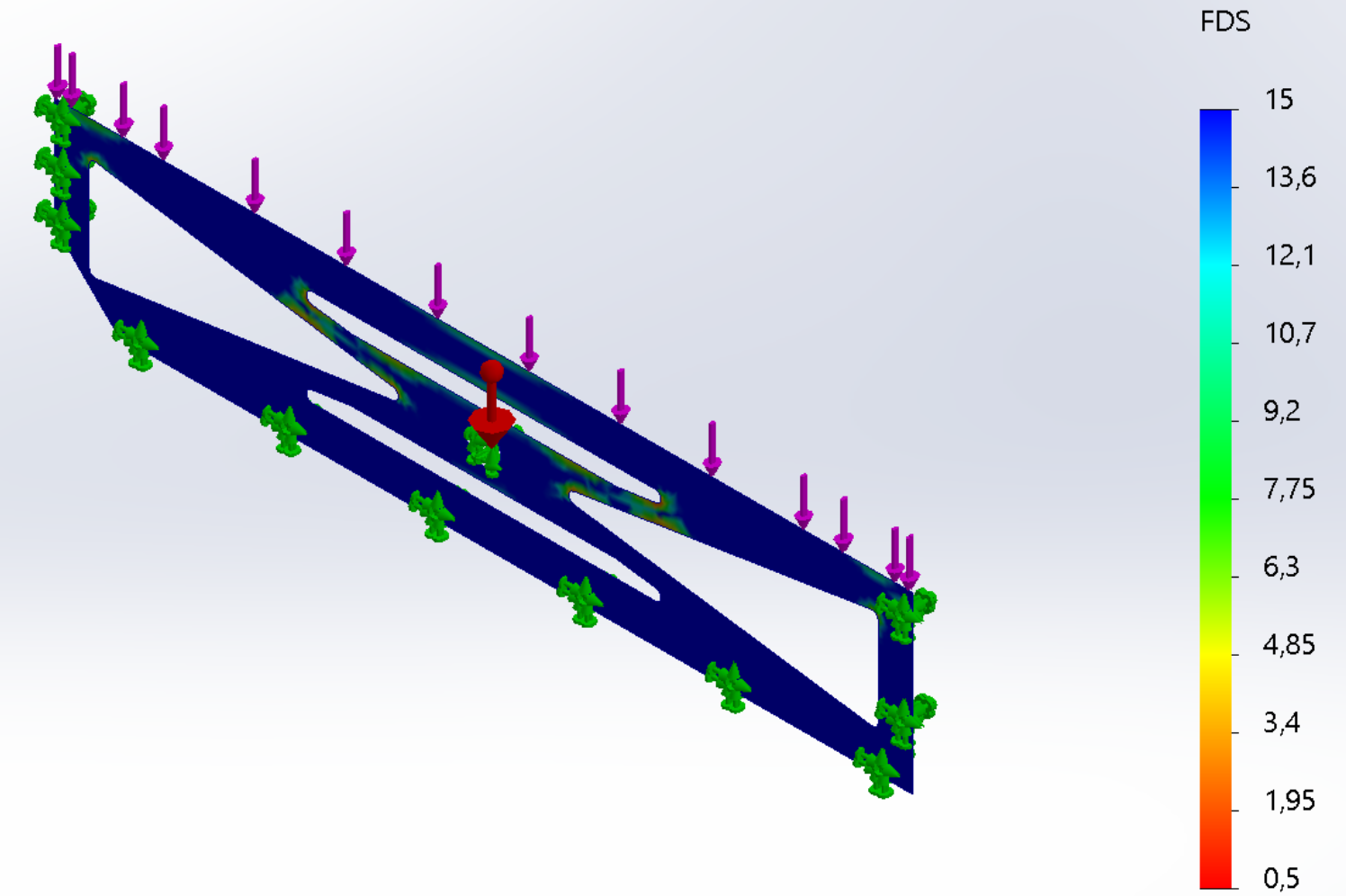

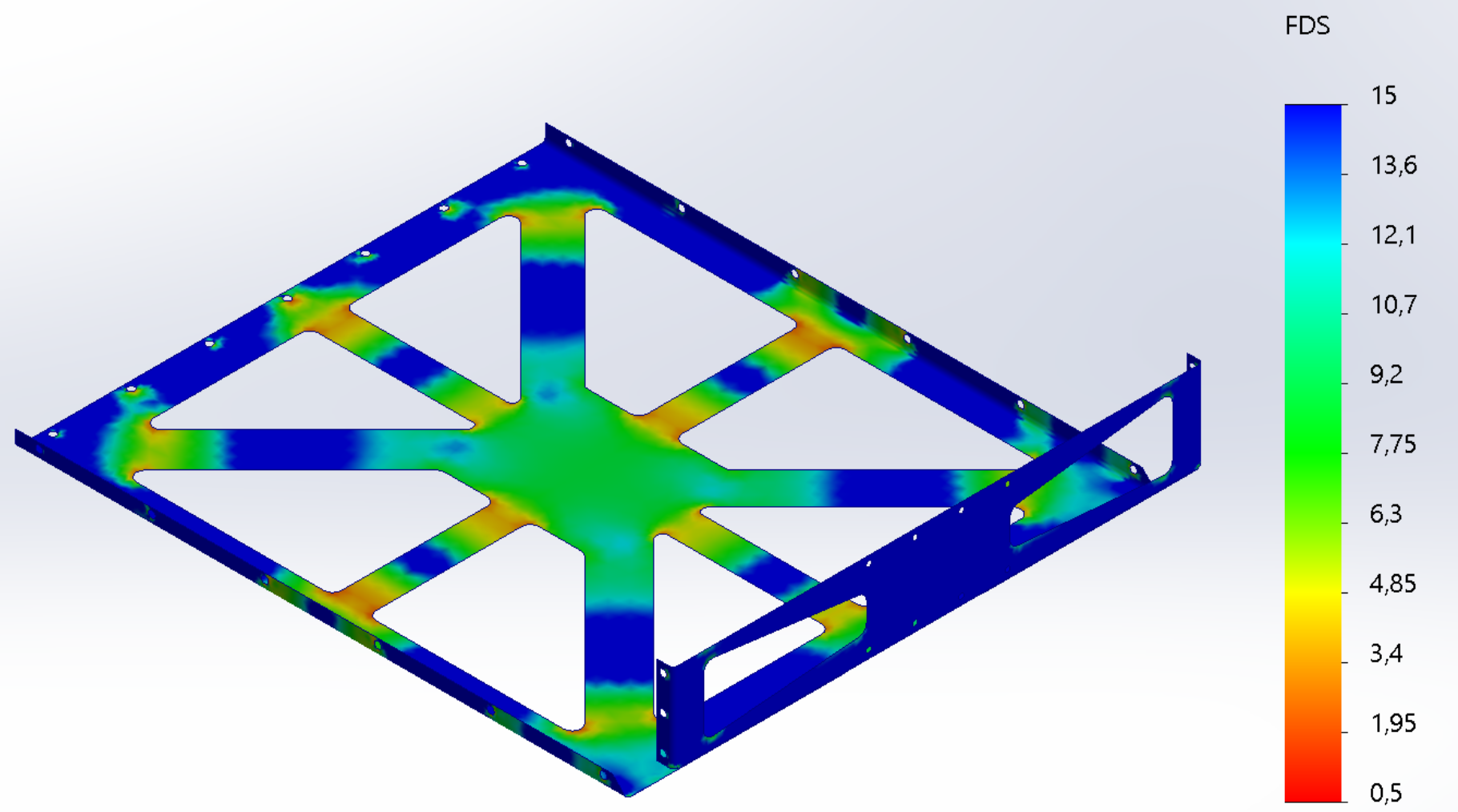

Rover's Body

The rover's body, known as its skeleton, protects the electric systems and computational elements from the Martian environment. It is strong and serves as the transport method like a 6-wheeled car, while safeguarding the electronics from dangers like water, dust, and sun irradiation.

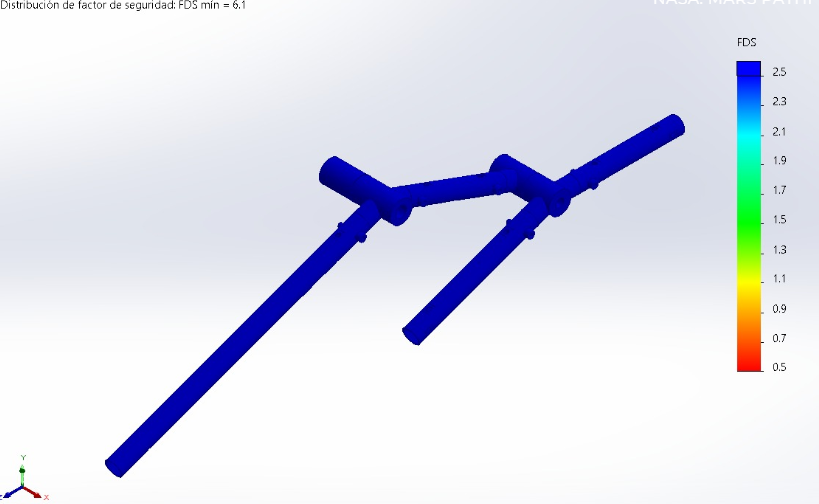

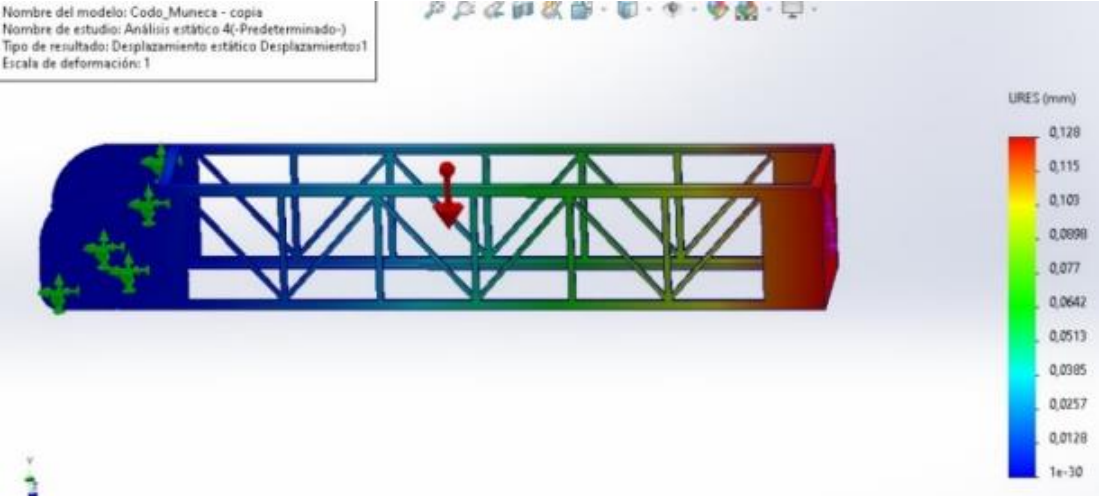

The chassis design process was challenging. We aimed to achieve a geometry that was both lightweight and strong enough to withstand significant forces. Simulated models tested for various types of stress revealed the best profiles to support the rover’s 70 kg total weight and external forces.

Body Specifications

| Component | Specification |

|---|---|

| Chassis body | 619 mm x 765 mm x 163 mm |

| Manipulator support | 196.5 mm x 221 mm x 63 mm |

| Overall length of manipulator | 1356 mm |

| Weight | 65 kg |

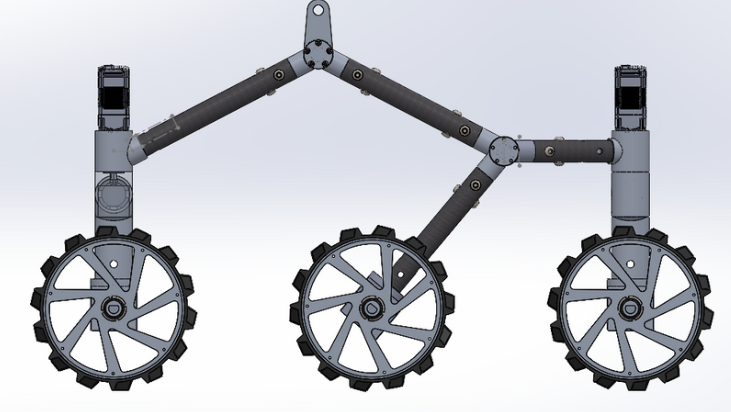

Wheels & Suspension

All of the six wheels were designed for hard terrains such as deserts or Mars' floor, ensuring they don't get stuck in the sand. At the same time, the suspension was designed for both hard and soft surfaces, securing all the rover's components as safely as possible from falling out or being damaged due to the rover's movement.

The suspension design follows a buggy-type structure, ensuring that the rover remains stable during sudden changes in inclination or height, as long as these changes are not overly extreme. Additionally, the machining was done manually using materials like aluminum and carbon fiber to ensure both strength and lightness. To meet all these requirements, numerous models were evaluated, and ultimately, the most efficient design was chosen based on weight, material usage, and functionality.

Brain

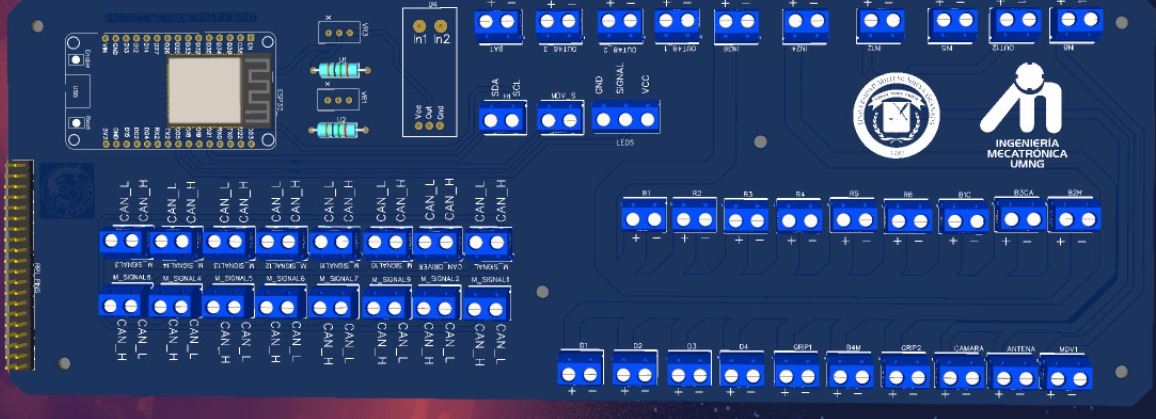

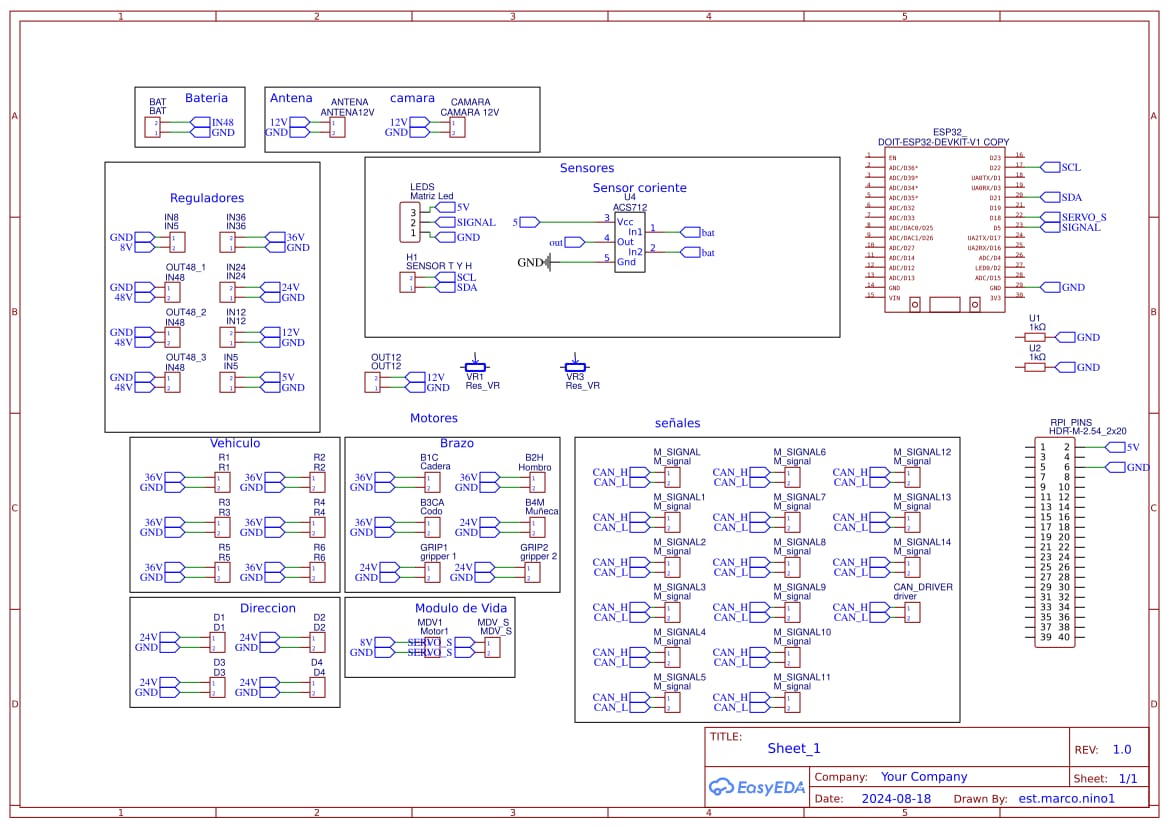

The main computational system is a Raspberry Pi 4B (8GB) paired with one ESP32 microcontrollers for efficient data handling and communication. The RPi processes live video footage from the external camera, while the ESP32 modules collect and transmit sensor data.

These microcontrollers were chosen for their compatibility with Python, real-time data transmission, and support for both analog and digital sensors. Their simplicity accelerates programming and future upgrades.

Specifications

| Feature | Details |

|---|---|

| Storage | 32GB microSD |

| Speed | 1.8 GHz (Quad-core) |

| Connected Devices | Maxon Motors, NEMA Controllers, Endoscopic Camera, ESP32, GPS, Antenna |

Eyes

The rover is equipped with a SIYI HM30 camera for low-latency live video streaming, perfect for remote operation. An additional endoscopic camera mounted on the robotic arm facilitates precise manipulation of objects in challenging environments.

Robotic Arm

The robotic arm features five degrees of freedom (shoulder, elbow, wrist pitch, wrist yaw, and wrist roll) plus an additional gripper, designed to maximize versatility and precision during operations. Each joint is equipped with high-torque servos to ensure stable and accurate movements, even under challenging conditions.

Innovative Cable System

The elbow joint incorporates an innovative cable system (guaya) that provides enhanced flexibility and strength. This system reduces the need for complex internal mechanisms by using tensioned cables to transmit forces and control the joint's movement. The implementation of this system significantly reduces weight, ensuring the arm remains lightweight and balanced. Additionally, the cable system enhances the reliability of the elbow by minimizing wear and tear on mechanical components, making it ideal for extended operations in harsh environments.

Kinematic Control with Inverse Jacobian

The arm's control system is based on kinematic control using the inverse Jacobian method. This advanced mathematical approach calculates the required joint angles to achieve a specific position or orientation of the gripper in 3D space. This allows the robotic arm to move with high precision and adaptability, even in complex scenarios.

The control system offers two modes of movement:

1. Normal Mode

Designed for standard operations, this mode allows the arm to move smoothly to predefined positions with minimal user intervention. It is ideal for general tasks where speed and reliability are priorities.

2. Fine Adjustment Mode

This mode enables precise and incremental movements, making it suitable for delicate tasks requiring high accuracy. It is particularly useful for manipulating small objects or working in confined spaces where precision is critical.

Its structure incorporates precise cabling and servo support, achieving functionality and durability while minimizing weight to avoid unbalancing the rover. The gripper is designed to handle objects of varying sizes and shapes, making it ideal for a wide range of tasks in exploration and manipulation.

Special attention was given to the joint mechanisms and weight distribution to ensure optimal performance without compromising the rover's stability. The arm's control system allows for smooth and coordinated movements, critical for tasks requiring high precision.

Power Supply

The modular power system includes a 48V, 1kW battery designed for easy replacement and reliable performance. Multiple power levels cater to various components of the rover, ensuring efficient and stable operation.

Voltage Distribution

| Voltage | Components Powered |

|---|---|

| 36V - 800W | Traction Motors (6), Elbow, Hip and Shoulder (3-Arm) |

| 24V - 480W | Steering Motors (4-direction), Wrist, Gripper (3-Arm) |

| 12V - 240W | SIYI HM30 Camera, Antenna |

| 5V - 50W | ESP32 Microcontroller, RPI and Led Matrix |

Controllers

The rover's control system is built on advanced theoretical models and motion matrices, ensuring precise monitoring and adjustment of key variables such as wheel angles, speeds, and servo operations. This provides smooth and reliable control of the rover's movement and tasks.

The motors are equipped with drivers that utilize the CAN protocol, enabling robust and efficient communication for speed and position control. This protocol ensures that commands are transmitted with minimal latency, improving the overall responsiveness and accuracy of the system.

Additionally, a comprehensive dynamic analysis was performed to calculate the minimum torque required for each motor. This analysis considered factors such as terrain resistance, load distribution, and the rover's weight. These calculations ensured that all motors were adequately specified to meet the operational demands while optimizing energy efficiency.

Communications

The communication system of the Chaquen Rover integrates advanced technologies to ensure robust data exchange and reliable performance during operations. Two artificial intelligence (AI) models enhance its functionality:

1. ArUco Marker Localization

This AI model detects ArUco codes and calculates their approximate position relative to the rover in x and y coordinates, using the rover as the reference point.

2. Environmental Analysis

This model analyzes the surrounding environment and determines whether it is habitable or non-habitable based on real-time data collected by the rover's sensors and camera.

Camera System

The camera operates on a dedicated communication channel, streaming live video to the base station via LAN protocol. The base receives the video feed using the following RTSP configuration:

video_url = "rtsp://192.168.144.25:8554/main.264"This setup supports real-time visualization on up to two devices simultaneously, ensuring effective monitoring of the rover's operations.

Local Server and Database Integration

The rover relies on a local server hosted on XAMPP, enabling seamless communication and data synchronization. The system operates as follows:

1. Database Synchronization

The Raspberry Pi (RPI) queries the database every second, which is automatically updated by the camera to reflect incoming commands.

2. Real-Time Updates

The RPI updates the database with critical information, including the rover's location and the position of the robotic arm's degrees of freedom.

These interconnected systems ensure efficient data management and communication between the rover and the base station, enabling precise operation during missions.